Here’s a not-at-all-secret fact you might not know about me—I worked at Webs for almost seven years in various capacities.

All photos in this post © Webs/yarn.com

Webs is a huge destination for many in the fiber community, and I saw countless stunned, amazed, and overwhelmed reactions from first-time customers during my time working there. Part of that was spent working the retail floor, so I’ve lived through multiple Tent Sales, busy Saturdays, holiday shopping seasons and regular old weekdays! If you’ve never been to Webs at all, or if you’ve shopped there before but never during a big sale, keep on reading for my insider’s perspective on how to shop America’s largest yarn store.

The front half of the retail store.

The Basics: Skip this part if you’ve been before!

- The retail store is in Northampton, MA. If you’ve ordered online before and saw Easthampton, MA printed on your invoice—that’s the shipping warehouse. Don’t go to that address hoping to shop!

- The front half of the store is full-priced items, most of which are eligible for the Webs Discount.

- The back half is known as the warehouse, and that IS shoppable and is different than the shipping warehouse. (Yes, confusing nomeclature.) The warehouse is full of Webs’ own Valley Yarns Line, and yarns marked down in price like closeouts and discontinued yarns, occasionally overstock and so on.

- Bathrooms are in the front of the warehouse.

- A few years ago the store started printing ‘store maps’ that are near the front door. Since the store and warehouse are (mostly) sorted by weight, this points you in the general direction if you already know what you need. See what these maps look like here.

- To work in the retail store, staffers must have fiber knowledge and preferably multiple disciplines. So don’t hesitate to ask them questions! Depending on the day of the week, you might get unlucky if say, you have a complex weaving question and the staff members who weave aren’t working that day, but generally there is good coverage for most questions.

The back half of the retail store, or the warehouse as its called. Yes, it's shoppable!

Hack: Stop at a bathroom before hitting the store.

Especially during busy sales or weekends, don’t get stuck waiting in line for the bathroom when you first arrive—stop right before you reach the store! If you’re coming from I-91 North or South and get off at Exit 18, there’s a gas station with a Dunkin Donuts on your right before you reach the turn for Service Center Road. You can also stop at that gas station if you’re coming up from Holyoke on MA Rte 5/10. If you’re coming down 5/10 from Hatfield, you’ll pass multiple gas stations and fast food places before you hit the main intersection of downtown Northampton.

Have a plan.

How prepared you want to be is up to you. I suggest bringing a list that at the very least reminds you of projects you’d like to work on or gaps in your stash, ie ‘yarn for Tea Leaves Cardigan and Color Affection’ or ‘purple fingering weight yarn.’ This can keep you in check if you’re on a budget and become intoxicated by yarn fumes, or if you get overwhelmed easily and forget what you need. A more thorough list of specific yardages is helpful, especially if your pattern calls for a yarn that is no longer available, a little known indie yarn, or a yarn that Webs doesn’t carry. Telling a staff member you need 1000 yds of DK weight yarn for a certain type of project will get you to the right shelves faster. Knowing the names and colors of yarns you’ve been eyeing online is even better! If you can bring your pattern with you, whether it's on paper or your tablet/phone, that can help shortcut things.

Tempting shelves of Madelinetosh!

Hack: In-Store Pickups

If you know you HAVE TO HAVE a certain yarn, I suggest ordering it in advance with an In-Store Pickup. In a nutshell, Webs has both a physical retail location (in Northampton) and a shipping warehouse (in Easthampton), where the bulk of inventory lives. The website displays the total amount of inventory for an item, meaning there’s no way for you to know how much of that total will actually be in the store when you arrive to shop. Ordering an In-Store Pickup guarantees that yarn will be in the store, reserved for you when you arrive so you’re not disappointed. You can read the guidelines on Webs’ FAQ page (note there’s a lead-time). I would place an ISP if your order falls into one of these scenarios:

- The total amount in inventory is close to the number of skeins you want (ie, inventory says 7 and you want 5.)

- You want a large quantity in one dyelot, like for a sweater or blanket project. Especially so if you are looking at hand-dyed yarns!

- The yarn is limited edition, a closeout, or otherwise a one-time-only, get-it-while-you-can scenario.

You can always place an order in the store at checkout for any missing or out of stock yarn to be shipped to you when it arrives, but you know…then you have to wait.

When to shop.

This is not a hard and fast science, since you never know who will show up! To avoid crowds try to shop on weekdays and in the middle of the day. If you must shop on a Saturday or during a sale, I’ve noticed crowds tend to thin around lunchtime as people leave to grab food, so if you can wait and pop in then you’re likely to have more elbow room and less competition for that skein you’ve been eyeing.

If you're planning on traveling from out of the area and are looking for local accommodations, consider checking the calendars of Smith College, which is located right in Northampton, and the other four colleges in the area before planning your trip. Rooms can be hard to find around graduation, which frequently overlaps with Tent Sale, and during other big events of the year. Also note that Webs isn't too far from Rhinebeck, so many people will duck into the store on their way to or from their Rhinebeck weekend causing some extra traffic on those dates.

These are the tents of Tent Sale.

Expert Level: Tent Sale.

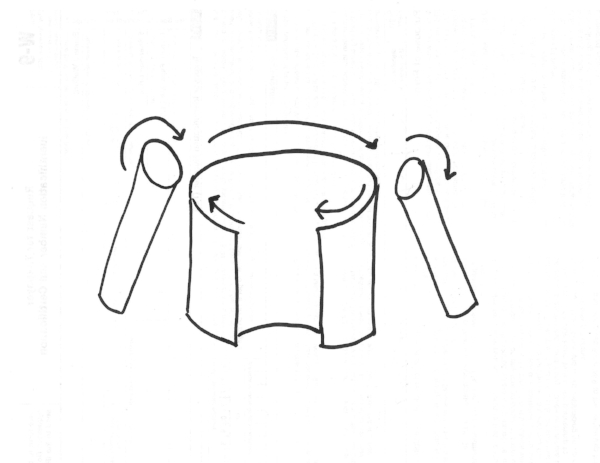

The annual Webs Tent Sale is a weekend event that occurs in May as part of the extended Anniversary Sale. This year it's May 20 & 21, 2017. Along with yarns from the Anniversary Sale that are already on sale, lots of special deals get put out under big tents in the parking lot. Stuff like a bag of yarn for only $10! It’s a really big deal—bus loads of knitters will field trip to the store on Tent Sale Saturday! If you have a chance to come to the store on a regular day first to get acquainted with the layout, that will help you navigate more easily. Saturday is the most popular day, since it’s the only day of the weekend that includes the Fleece Market of independent vendors selling their wares in the parking lot. To survive Tent Sale:

- Go to the bathroom before arriving. Really. The women’s bathroom at Webs only has three stalls and the men’s bathroom is single-person.

- BYO water or beverage of choice.

- Bring a well-planned list so you can be as self-sufficient as possible. There’s not enough staff to go around, especially in the morning, and you’ll save time if you can find things yourself rather than having to wait behind 10 other people to ask a staff member.

- Tent Sale is an all-hands-on-deck event, so there will be Webs staff from the warehouse or other departments working who are not fiber crafters and don’t know where anything is. Be patient with them! This is also not the weekend to ask for intricate, hands-on help with your projects in progress as there are just too many people attending.

- If you can arrive slightly before or right at opening, you can get directed to a parking spot faster and be ready to spring as soon as things get going. There is usually a very narrow window at the beginning of Saturday where things are easily navigable, and then it’s a madhouse until early afternoon. Before then, the line to checkout stretches the length of the store and back into the warehouse!

- Unless you really, really want to have first crack at special deals or want to shop the Fleece Market, I’d say come late afternoon on Saturday or wait til Sunday for less chaos.

Have you shopped at Webs before? What's your favorite tip for a newcomer?